- Masa Tool Microconic

MASA Tool, Inc. is a company founded with the mission of bringing micro machining solutions. The name "Microconic" comes from the sophisticated grinding techniques that were developed for their collets. Theyprovide the advantages of extreme accuracy, high gripping force, and high tolerance for workpiece size differentials. Each finger of the collet has a separate conical surface that acts to apply the gripping force with superb accuracy.

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, TF15, TF16, TF20, TF25 or TF37 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge.

The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, TF15, TF16, TF20, TF25 or TF37 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge.

Microconic Cartridge

The Microconic™ cartridge fits into your CNC lathe or swiss machine and transforms the spindle into a highly accurate miniature work holding system.

|

Installing the Microconic cartrdige enables your shop to convert all of your facilities turning machines spindles to a one universally sized Microconic collet for your small diameter workholding.

All cartridges are precision groundhigh-chromium tool steel. Our manufacturing tolerance is 3µm (.0001") and we guarantee our cartridges to be within 5µm (0.0002") in production use in your machine . The robust design and materials ensure reliability and longevity in the most demanding production environment, while providing extreme accuracy. |

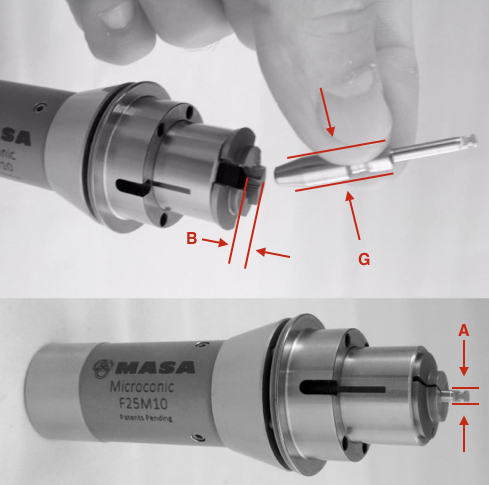

Overgrip collets

Over-grip collets, also referred to as over-the-shoulder collets, are used in a pick-off /sub-spindle when it is required to clear a shoulder and grip on a smaller diameter beyond the larger diameter.

|

The Drill blank pictured at the left is a good example of this kind of part. Extra spread is required to open the collet wide enough to go over the larger diameter. The grip diameter (A), the width of the grip land (B) and the largest part diameter to reach over (G) are required to choose the off-the-shelf over-grip collet for your specific part. Microconic over-grip collets are a great way to expand your machine's capability, eliminate secondary operations and reduce cycle time |

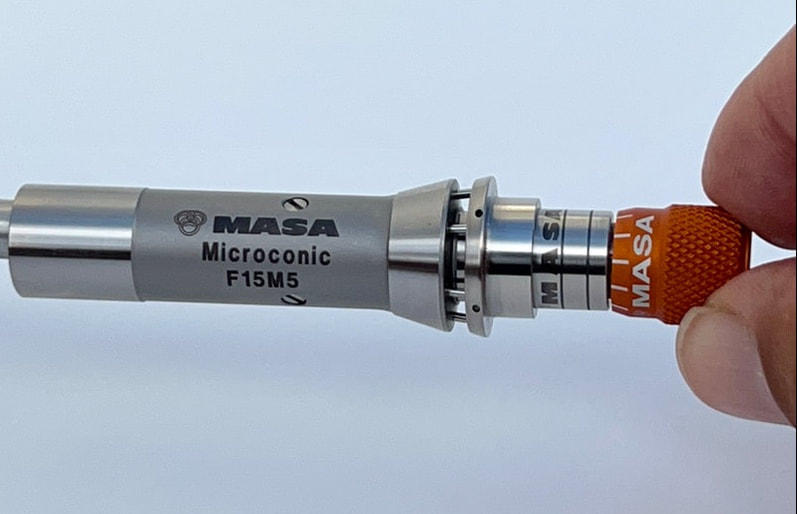

Micrograd Dial Wrench

Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

|

The Micrograd™ Dial Wrench is included with the purchase of any Microconic Cartridges. The Micrograd™ Dial Wrench provides a method of precisely setting clamping pressure on both the Microconic collets and an Microconic overgrip collets . It can be adjusted in metric increments of 0,02mm and imperial increments of .001" |

17 May 2023