- Whizcut

Erik Schmidt, the founder of WhizCut, is a well known figure within the metal cutting industry as the inventor of the Snap-Tap threading attachment in 1965. Since then, he has developed many revolutionary products including his invention of the WhizFix tool holder system in 1996. Mr. Schmidt also developed the geometry’s of the WhizCut inserts. WhizCut understands the day-to-day challenges that users of Swiss automatic lathes are up against and are committed to making life easier for these users of around the globe. At WhizCut they try to find new solutions for existing problems within the world of small part machining. No matter if your work is in external cutting or internal cutting, they have the solutions to boost your production.

External Turning Tools for Swiss Lathes

WhizCut offers the widest range of external carbide inserts for Swiss type automatics / sliding heads on the market. Our goal is to offer great performing WhizCut tooling for all applications our customers need in their lathes.

|

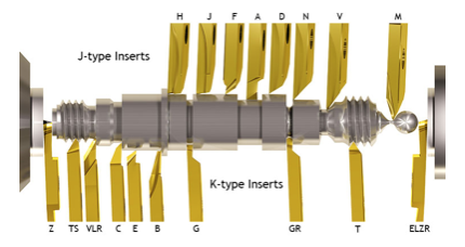

WhizCut inserts are divided into 2 different application styles; K-type for radial turning and J-type for front turning.

The tool holders for radial turning and front turning have been optimized for their targeted application. As a result the user of WhizCut inserts only need two types of tool holders to cover almost all external cutting tool applications. |

WhizAdjust- BackTurning on a Swiss CNC

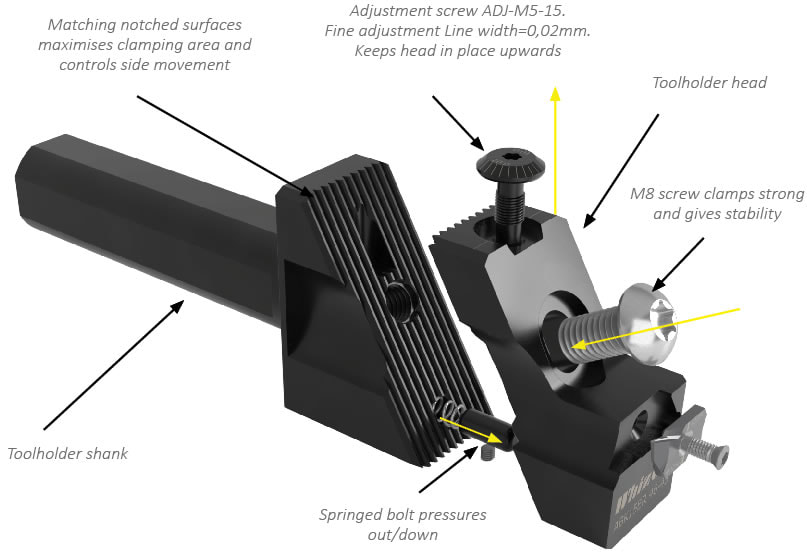

Fine-tune your way into the future of backworking, with WhizAdjust. It's the perfect for back turning on Swiss lathes. for turning against the sub spindle - with quick height adjustment and no loss of stability.

|

Quick: The fine-tune adjustment screw together with stable clamping makes it possible to modify center height. Loosen one clamping screw from the WhizAdjust head and shank - and the adjustment is done. It is as easy as that.

Stable: The shank and adjustable head are positioned together with serrated surfaces in X axis and the adjustment screw plus a spring in Y. The repeatability, by removing the toolholder and fastening it again, is under 0,005. |

WhizHip High Pressure Coolant System

WhizHip is a distribution system for high pressure coolant, capable of handling pressures up to 300 bar, and at the same time flexible for setup and tool changes. WhizHip performs great, leading to shorter machining times, less machine stops and a more consistent process.

The WhizHip distribution system is exactly this. It is developed so the user has a quick change connector and a flexible metal braided hosing. The metal braided hosing withstands the heat from hot chips shooting at the material and the system is developed to be used for up to 300 Bar (4351 PSI)

15 May 2023