|

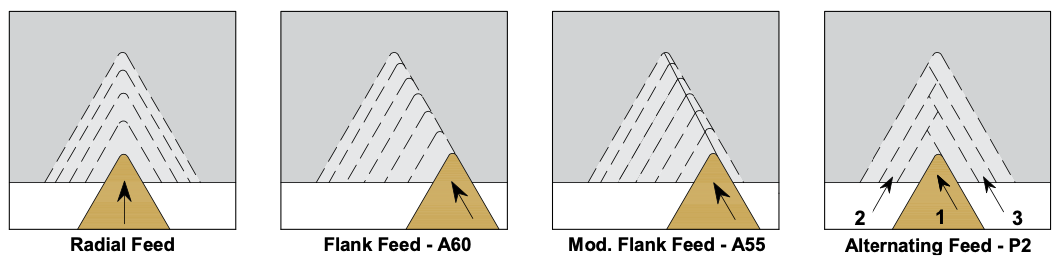

by Charles Colerich for Horizon Carbide Here are four guidelines to help improve your threading process when threading on a lathe. 1. Start Near the top of the SFM rangeAs a good rule of thumb, always start near the top of the Surface Foot per Minute Range for the material that is being threaded. Higher SFM reduces Built-up Edge, the major cause of poor tool life in threading. For Harder or more Abrasive Materials start in the Middle of the SFM range. Once setup is complete SFM can be adjusted for optimum tool life. Tough Micrograin Grade 310 reduces insert chipping from edge build-up at lower SFM and on parts under 1” Diameter. Formulas to calculate Revolutions Per Minute (RPM) and Surface Feet Per Minute (SFM) : RPM = SFM x 12 Divided by Part Diameter x 3.1416 SFM = 3.1416 x Part Diameter, Divided by 12 x RPM 2. Use the G76 Threading CycleAs a second good rule of thumb, use the G76 Threading cycle with Fanuc, Yasac and similar CNC controllers. If P1, P2, P3, & P4 parameters are available, use P1 for most applications. G76 - P1 removes equal amounts of material with every pass. P2 alternates between front & back cutting edges and should only be used on 6 tpi & coarser threads. 3. Set Depth of Cut for the 1st Pass at 20% - 30%Set the Depth of Cut (DOC) for the first past at 20-30% of the thread height per side. G76 controls the depth of cut for the remaining passes. To find the DOC for the 1st Pass multiply the PITCH by 0.6 to get the approximate THREAD HEIGHT. Multiply THREAD HEIGHT by 20 - 30% to get the DEPTH of the 1st Pass. Use less than 20% when threading hard materials or larger thread pitches. Do not use “Spring Passes” under .002 DOC Per Side. EXAMPLE: CALCULATING THE DOC FOR THE FIRST PASS ON A 1/2-20 THREAD 1” 20 =.050PITCH),(.050x.6 =.030 (THREADHEIGHT), .030x.3 =.009 (DEPTHOF1stPASS 4. Use the A55 Parameter to set the Infeed AngleMost CNC Lathe Controls offer a choice of A60, A55, A30 & A29. A60 is the default setting. A55 is equivalent to setting the compound feed on a manual lathe to 27.5°. In most applications A55 will double or triple tool life over A60.

0 Comments

|

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed