|

Whizcuts' WhizHip is a distribution system for high pressure coolant, capable of handling pressures up to 300 bar, and at the same time flexible for setup and tool changes. WhizHip performs great, leading to shorter machining times, less machine stops and a more consistent process. Swiss type automatic lathes running high pressure coolant systems with coolant through tool holder are getting more common. One of the challenges has been to use a distribution system which can withhold the high pressure wanted and at the same time also be flexible for setup changes or changing toolholders. The WhizHip distribution system is exactly this. It is developed so the user has a quick change connector and a flexible metal braided hosing. The metal braided hosing withstands the heat from hot chips shooting at the material and the system is developed to be used for up to 300 Bar (4351 PSI). This new system can also be perfectly combined with the WhizHip and WhizIn Toolholders from WhizCut all prepared for internal high pressure coolant. With these toolholders the perfect angle for optimal coolant is given the coolant shoots directly between the forming chip and the cutting edge. The WhizHip distribution system includes 3-, 5- or 8 way distribution blocks which can be easily mounted in the machine. It also incorporates flexible copper nozzles which can be quickly adapted to the right position as it will not twist in the coupling. We know all machines and applications are different so contact us to get the setup that suits your machine and application the best. WhizHip Features

For more information on Whizcut get in touch with our team!

0 Comments

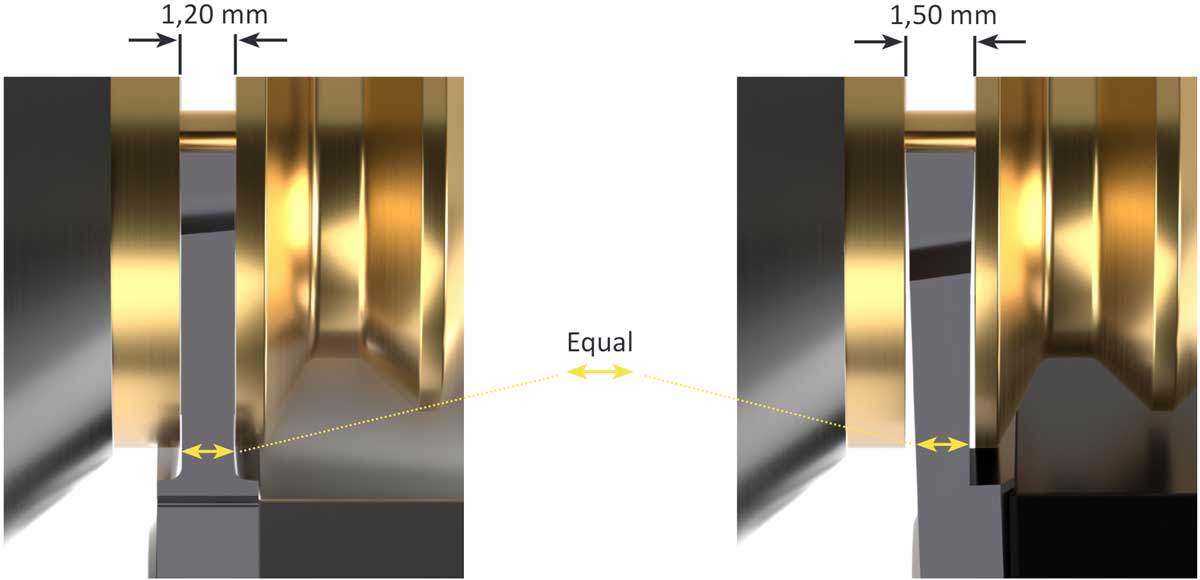

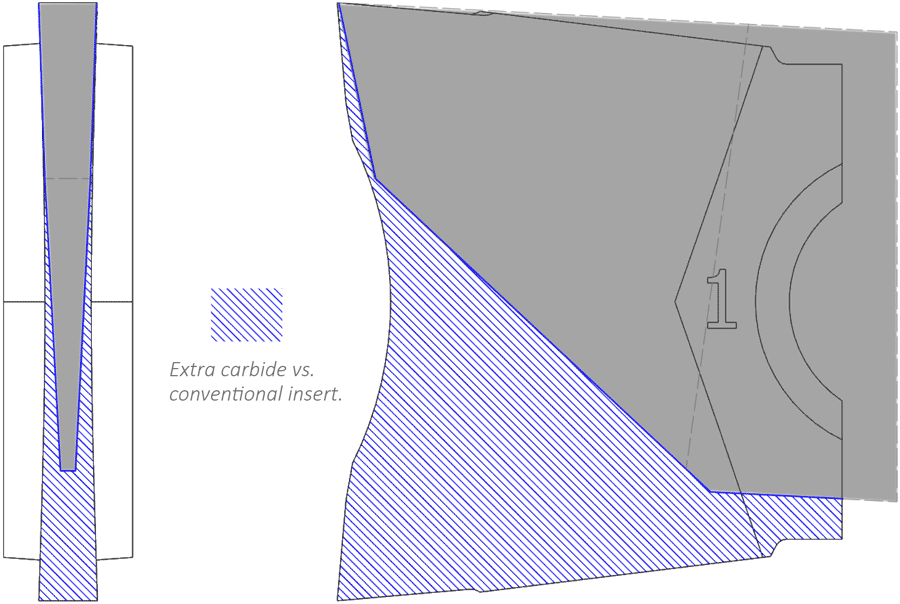

The power and strength is where it needs to be - times two. WhizCut has re-invented the parting off insert for the future. WhizTwin is a bold new insert that helps reduce waste material and has a cutting edge stability. The patent pending design of WhizTwin generates a cutting edge stronger than any other and a stability not seen before. The strength and increased stability of the cutting edge is maximised with two cutting edges at the front. This lets the toolholder be clamped in a more stable position with a smaller overhang from the toolholder plate - reducing instability and vibrations which are the main chal-lenges when parting off. Less material waste, less costs. WhizTwin is forceful, stable and overall brilliant. The narrow insert allows you to lower your production cost as you save material using it. Removing less bar material is great for you and also for the environ-ment. It’s a win win - with WhizTwin. Power up your parting off |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed