|

The article provides an in-depth look at MAQ's advancements in machining technology, particularly focusing on their innovative turning tool holders equipped with proprietary dampening technology. Ahmed Bousmina, a Mechanical Engineer at MAQ, offers insights into how these tools enhance efficiency and precision in the machining process. The discussion covers various aspects, including the versatility of tool designs, the significance of material choices, and the company's future directions. by Mariah Hellman

In an industry where precision and efficiency is paramount, MAQ has positioned themselves at the forefront of machining technology. Ahmed Bousmina, Mechanical Engineer at MAQ, sheds light on how the company is revolutionizing the machining process with its innovative tooling solutions, particularly focusing on turning tool holders equipped with proprietary dampening technology to combat harmful vibrations during machining. Innovating for efficiency and flexibility At the heart of MAQ’s product line are the turning tool holders, designed to accommodate a range of operational lengths and diameters, ensuring versatility for various machining tasks. “Our tools are categorized to simplify selection for our customers, focusing on the diameter and operational length rather than the total length of the tool, which is often irrelevant to the buyer,” Ahmed explains. This user-centric approach underscores MAQ’s commitment to providing solutions that genuinely meet the needs of operators and manufacturing professionals. Cutting-edge dampening technology What truly sets MAQ apart is the integration of dampening technology within their tool holders. This innovation significantly reduces vibrations that can compromise machining quality, allowing for smoother operations and higher precision. “We’ve divided our products into four main sections based on the tool’s diameter and the stick-out length, offering unparalleled performance across a wide range of specifications,” Ahmed says. Carbide reinforced and steel options When going into detail on the distinction between carbide-reinforced (CR) and full steel tool holders, Ahmed highlights how material choice is pivotal when machining at various lengths. “For longer tools where bending moments become a concern, carbide reinforcement on the tool’s back end ensures rigidity and optimal performance,” he noted. This nuanced understanding of material properties and machining dynamics is a testament to MAQ’s expertise and innovation in tool design. Modular and monoblock configurations MAQ offers tools in both modular and monoblock configurations, catering to different machining requirements. The modular system provides flexibility, allowing for head changes to accommodate various machining processes without the need for multiple tools. On the other hand, monoblock tools offer a rigid, integrated solution for specific applications. “This versatility ensures that our customers can achieve the best results with minimal tool changeover time,” Ahmed adds. Future directions and market expansion Looking ahead, MMAQ is focused on expanding its product range to provide for even more specialized needs. Already today, MAQ offers the widest range of products on the market, with the smallest tool measuring 6mm, and the largest up to 80mm in the standard range, while the capabilities span up to 350 millimeters in diameter and 5,5 meters in length. The technology is scalable, which enables everything from medical components requiring miniature precision to large-scale parts in the oil and gas or defense sectors. This, ensuring that MAQ’s technology is versatile enough to meet a broad spectrum of industry demands. Looking to the future, the goal is to expand the product range even more, to meet an even wider number of industries. “Our aim is to simplify machining worldwide, making it more efficient, precise, and cost-effective for our clients,” Ahmed concluded. With a relentless pursuit of innovation and a keen eye on the evolving needs of the machining industry, MAQ is not just a tool manufacturer – but a partner in machining excellence, paving the way for future advancements in the field.

0 Comments

For an air-driven pump manufacturer, trying to remove small burrs from the inside of aluminum sleeves proved to be a time consuming and expensive operation-especially sending the parts out for manual deburring. But anew system, consisting of a resilient-basedhone, has resulted in a more efficient process and a smoother finish. Haskel Inc. (Burbank, CA) manufactures a variety of compressed air driven pumps for use in a cross-section of industrial applications. The company experienced quality control issues with the manufacture of its miniaturized models. Burrs are created in the airdrive system's aluminum sleeve, which must meet specification of 16 micro-finish. To produce the sleeve, which is about "2 long, Haskel machines the part from 13/16" diameter aluminum bar stock. The sleeve is then put on a conventional drilling machine, where an operator drills two series of holes around the sleeve. One series has 1/8" holes, while the other has 3/32" holes. During the drilling process, burrs are produced along the inside diameter of the sleeve. If these burrs remain, the pump can be damaged. For instance, a spool slides back and forth like a piston with O-rings inside the sleeve to open and close the holes. During this cycling action, a loose burr can cause excessive wear on the O-rings. After drilling, the sleeve is taken to a workstation where an operator uses ano-burr tool to put an edge break on each one he holes. Even after this step, very small burrs still remain lodged inside the sleeve. In the past, Haskel sent the sleeves to an outside vendor where the minute burrs were removed in an entirely manual operation - a costly and time consuming process. After the deburring, the sleeves were then returned to the plant for as- sembly. Increase EfficiencyA new deburring/finishing system called Flex-Hone@ offers a solution to eliminate small burrs. Manufactured by Brush Research Manufacturing Co., Inc. the system consists of a resilient-based hone with abrasive laminated to the ends of bigh-density nylon fila- ments. At Haskel, the 1 mm diameter, 180-grit silicon carbide hone is placed in a standard drill chuck. The system has resulted in a smoother, more efficient operation. After the preliminary deburring step, the sleeves are taken to the deburring station.

At this point, the operator places a pan of kerosene beneath the hone and loads the pan with the sleeves, which become lubricated. At the same time, the drill motor is activated, rotating the hone at about 100 pm. The operator then lifts a sleeve to the revolving hone and makes five or six passes. Inside the sleeve, a spring-like action causes the tool to knock out any burrs remaining in the holes.The parts are then ready for burnishing. With an annual production of 10,000 - 20,000 sleeves, the company uses two or three hones per standardorder of2,500 parts. For Haskel, the Flex-Hone® tool provides better quality control and cost savings, paying back the cost of the system many times over. The company now saves 40% of the total cost of producing the part as opposed to jobbing the work out. If you would like more information, please contact one of the people on our team to test a Flexhone. Whizcuts' WhizHip is a distribution system for high pressure coolant, capable of handling pressures up to 300 bar, and at the same time flexible for setup and tool changes. WhizHip performs great, leading to shorter machining times, less machine stops and a more consistent process. Swiss type automatic lathes running high pressure coolant systems with coolant through tool holder are getting more common. One of the challenges has been to use a distribution system which can withhold the high pressure wanted and at the same time also be flexible for setup changes or changing toolholders. The WhizHip distribution system is exactly this. It is developed so the user has a quick change connector and a flexible metal braided hosing. The metal braided hosing withstands the heat from hot chips shooting at the material and the system is developed to be used for up to 300 Bar (4351 PSI). This new system can also be perfectly combined with the WhizHip and WhizIn Toolholders from WhizCut all prepared for internal high pressure coolant. With these toolholders the perfect angle for optimal coolant is given the coolant shoots directly between the forming chip and the cutting edge. The WhizHip distribution system includes 3-, 5- or 8 way distribution blocks which can be easily mounted in the machine. It also incorporates flexible copper nozzles which can be quickly adapted to the right position as it will not twist in the coupling. We know all machines and applications are different so contact us to get the setup that suits your machine and application the best. WhizHip Features

For more information on Whizcut get in touch with our team!

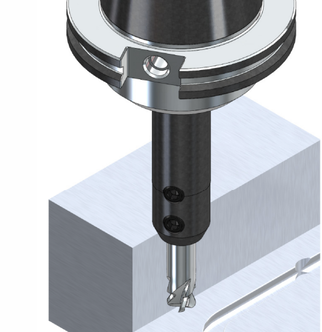

Tapmatic, a pioneer in tapping and part marking solutions, has introduced the DeBurr-Z CNC Deburring Tool with Compression and Extension Float, a game-changing tool designed to streamline the deburring, chamfering and engraving process on CNC machines. written by Bernard Martin The NEW DeBurr-Z from Tapmatic deburring tool not only showcases the ability to efficiently remove burrs directly on the CNC machine but also eliminates the need for time-consuming manual labor. What sets the DeBurr-Z apart is its exceptional versatility. Floating in both compression and extension, this tool enables the cutting tool to adeptly trace the top or underside edges of the workpiece. This proves to be particularly advantageous in situations where these edges are not clearly defined, as often encountered with castings and cross holes. The DeBurr-Z takes versatility to a new level, allowing for precise deburring regardless of the intricacies of the workpiece. Fine-tuning the DeBurr-Z's performance is a breeze. With a simple turn of the knurled sleeve, operators gain the ability to adjust the force applied during the deburring process. This flexibility empowers users to increase or decrease pressure based on the material being machined and the desired edge break, all achieved without the hassle of disassembly or changing springs. USE AS AN ENGRAVING TOOL The DeBurr-Z can not only deburr and chamfer parts it can also be used as an ENGRAVING TOOL! The DeBurr-Z can not only deburr and chamfer parts it can also be used as an ENGRAVING TOOL! Beyond deburring, the DeBurr-Z steps can also perform engraving. Its compression float feature facilitates a faster approach to the workpiece, proving especially effective for marking on curved surfaces. This dual functionality adds to the tool's appeal, making it a versatile asset for machining tasks beyond traditional deburring. The DeBurr-Z not only contributes to precision but also enhances the lifespan of cutting tools. Thanks to its adjustable compression force, it aids in prolonging the life of cutting tools, simultaneously speeding up the machining process by enabling faster approach feed rates. This dual benefit significantly boosts overall efficiency and reduces production time, aligning with the demands of modern manufacturing. Ensuring a seamless integration into existing workflows, Tapmatic's DeBurr-Z is designed for user-friendly programming and easy installation on CNC machines. This ease of use allows operators to capitalize on its benefits without extensive downtime, further emphasizing its practicality in real-world machining scenarios. The DeBurr-Z CNC Deburring Tool with Compression and Extension Float is another revolutionary addition to the CNC machining landscape from Tapmatic. Its ability to float in compression and extension, coupled with adjustable force and compatibility with a variety of cutting tools, positions it as a versatile and indispensable tool for precision deburring and chamfering applications. With the DeBurr-Z, Tapmatic continues to set the standard for innovation in the CNC machining industry. The miniaturized B-Safe X Systems can be installed directly on your spindle guaranteeing real-time monitoring, as well as reducing machine downtime by predicting malfunctions. In precision machining, where every micron counts and every vibration matters, the search for the perfect balance between precision and performance has been ongoing for decades. Enter the B-Safe X System from Balance Systems, a true game-changer in machine tool monitoring. This innovative solution offers manufacturers a powerful tool to achieve the highest levels of precision and efficiency, reducing downtime, minimizing tool wear, and ultimately elevating the quality of your machining operations. The Need for Precision in MachiningPrecision machining demands tools and equipment that can deliver the utmost accuracy and efficiency. In an industry where even the tiniest discrepancies can lead to costly errors and suboptimal results, maximizing machine uptime is essential. The B-Safe X System, developed by Balance Systems, is setting new industry standards by addressing the critical issue of machine tool monitoring head-on. The B-Safe X System is much more than just monitoring; it's a comprehensive, state-of-the-art system designed to transform the machining process. The integration of different kind of vibration sensors guarantees a complete signals analysis on a wide frequency range. The presence of a microprocessor with integrated memory allows local detection and memorisation of collision phenomena, unbalances, overloads, anomalies of the working cycle, tools wear and bearings diagnostics. The always-connected B-Safe HMI is a software that allows interaction multiple sensors at the same time and is available in different languages and layouts. It can be installed on PCs or machine tools control panels that run Microsoft Windows 7, 8.x or 10.  The B-Safe X System can be installed directly on your spindle guaranteeing real-time monitoring, as well as reducing machine downtime by predicting malfunctions. It includes Collision Detections, Blackbox Logbook, Spindle Check-up Functions for Preventative maintenance, and most importantly, Continuous Monitoring even during power off. B-Safe X System Key Features

Unlocking the Potential of Precision MachiningThe B-Safe X System from Balance Systems is not merely a piece of equipment; it's a promise of precision. With its ability to address the challenges of balance in precision machining, it has the potential to redefine the landscape of modern manufacturing. As industries continue to demand tighter tolerances and higher-quality output, solutions like the B-Safe X System will become increasingly essential.

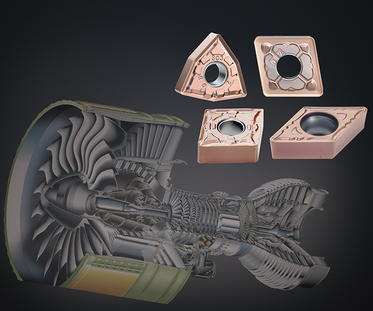

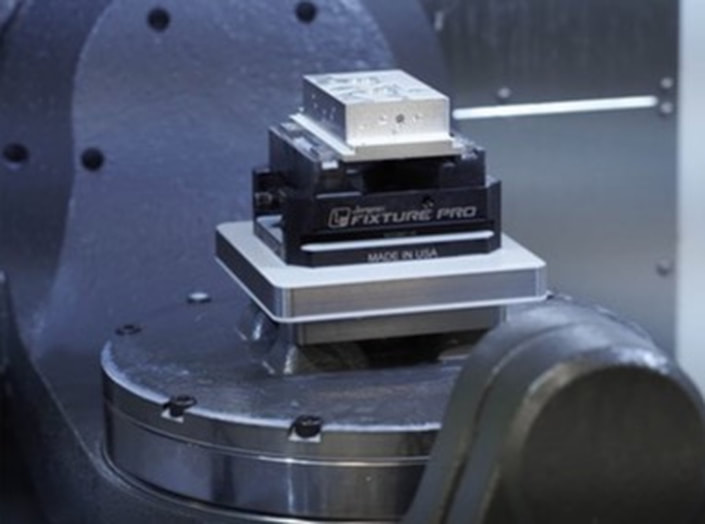

Balance Systems has taken a giant leap forward with the B-Safe X System, providing manufacturers with an invaluable tool to achieve unparalleled levels of precision in machining. As we look to the future of precision machining, innovations like the B-Safe X System will undoubtedly play a pivotal role in shaping the industry and driving excellence in manufacturing. Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation. Five-axis machining has built its reputation in the metal manufacturing world through the many advanced machining strategies that are impossible without the additional rotational axes that set it apart. However, many manufacturers have found great benefits in 3+2-axis manufacturing techniques, using the rotational axes to reduce setup time. This approach can provide a firm foundation for highly automated machine cells such as the ones I found at Clippard Manufacturing, a Cincinnati-based valve manufacturer and machine shop. Moving to Five AxesClippard began in the 1930s as a manufacturer of radio parts. Its early claim to fame came during World War II, when it manufactured coils for the Allies’ radio-based proximity fuse — one of the most successful weapon technologies developed for the war. Over subsequent decades, the company pivoted to pneumatic valves for various industries, especially the medical industry. More recently, the company has also begun working as a contract manufacturer of medical parts, putting its experience meeting the exacting standards of the medical industry to further use. The company’s first foray into heavy automation was in its fleet of 20 Swiss-type lathes, which found success working lights-out. Using this success, Manufacturing Engineer Alex Werdman convinced the company to invest in a five-axis Haas UMC 500 SS with a 16-station pallet changer to perform work that had been done on three-axis mills. The company made this investment with the intention of developing lights-out processes for the machine cell, but getting to that point meant investing in more than just the machine tool. One of the major draws of a five-axis machine was the ability to dramatically reduce setup time by machining multiple faces of parts in a single setup. According to Werdman, the move to the five-axis Haas made the jump to high-mix medical work much easier. “Being able to reach more faces of the part reduced the setup time for secondary operations by a lot,” he says. “Jobs that took 45 minutes per part on a three-axis were down to 27 minutes.” CNC Programmer Kyle Shearer agrees, saying, “I might touch a part 17 times before and only four times now.” However, this strategy relied on workholding that provided the cutting tool as much access to the part’s faces as possible. At first, Clippard considered using dovetails, but after a conversation with Jergens representatives and distributors, the company opted for vises with modular jaws. “We thought we would have to use dovetails,” Werdman says, “but the vise has enough grip force and clearance to meet our needs.” The Fixture Pro system is a modular vise that can provide 3,500 pounds of clamping force while the minimal profile of the jaws can dramatically improve access to the part. This provides excellent rigidity for five-axis machining, with a variety of jaw options available to meet the grip and shape requirements of the part. “There are a lot of modular jaws that work right out of the box,” Shearer says. “And if we need a specific shape, we can machine our own jaws pretty easily.” While machining jaws takes time, it is still a major time saver compared to machining a dovetail into every single part for that job. The vise is also self-centering to make it easier to consistently set up the workpiece for a job, and its jaws feature a quick-change design with no need for tightening. The jaw base connects to the top jaws using a spring system and a wedgeshaped mount. The combination of the spring and wedge pulls the top jaws down and back, firmly locking them into place and creating a highly rigid connection. As far as Werdman was concerned, the benefits of the vise were clear. “It provided three things: faster setup, better clearance, larger options,” he says. Lights-Out MillingOf course, the long-term goal of the machining cell was to machine parts lights-out. In addition to investing in reliable workholding, the company installed in-process verification systems to detect tool wear and ensure part consistency. “We still need the CMM for paperwork,” Werdman says, but ensuring the machine tool is operating at its best at all times is still necessary for unattended machining.  This 16-station pallet changer enables Clippard to run the five-axis UMC 500 SS unattended. The Jergens five-axis vises played a key role in designing this cell, as they enable the cutting tool to access as much of the workpiece as possible while eliminating the need for machining dovetails into every part. Photo Credit: Chris Kern, Jergens And did this work pay off? “The Haas proved that five-axis machines were worth it,” Werdman says. “We could get 50 hours a month on the three-axis mills, and with fiveaxis we get 200-300 hours.” The success of the Haas spurred Clippard to invest further in five-axis machining with a Matsuura MAM72-35V, intended to both increase the volume of parts the company could produce lights-out and improve the precision of its fiveaxis machining. The Matsuura came standard with a 32-station pallet changer in a condensed footprint, dramatically increasing the capacity for lights-out machining. Like the Haas, it regularly puts in over 200 hours of machining time, mostly performing 3+2-axis machining. It can also pursue more aggressive machining strategies while maintaining the finish needed, as it can maintain a tolerance of ±0.0005 inches. Despite being one of the major benefits of five-axis machining, this kind of dramatic increase in capacity and production speed is often overlooked by machine shops. Not all fiveaxis machines produce near-net shapes or large contours, and shops like Clippard have found great success thanks to careful consideration of the machine cell as a whole. “The people in charge needed convincing,” Shearer says, “but once they saw how much more we could get done and how quickly we could do it, they were on board.” JMI CNC Tooling & Automation Appointed Exclusive Manufacturers Representatives for Achteck America1/9/2024 Jones Marketing Inc to manage Southeastern region industrial supply chain and technical support for Achteck Tool Technology Co., Ltd. December, 2023 - JMI CNC Tooling & Automation, widely recognized as a leader in the CNC tooling and automation industry in the southeastern United States, is thrilled to announce their recent appointment as the exclusive manufacturers representatives for Achteck America. This strategic partnership marks a significant milestone for both JMI CNC Tooling & Automation and Achteck Tool Technology Co., Ltd., as it combines the strengths of two industry powerhouses to deliver cutting-edge solutions to the manufacturing sector. Achteck Tool Technology Co., Ltd., known for its innovation and precision in tool manufacturing, has selected JMI CNC Tooling & Automation as the exclusive representative for their products in the the Southeastern United States. This collaboration aims to enhance accessibility and technical support to Achteck's advanced tooling solutions, providing manufacturers with state-of-the-art technologies to optimize their machining processes. "We are honored and excited to be appointed as the exclusive manufacturers representatives for Achteck Tool Technology," said Kenneth Jones, President at JMI CNC Tooling & Automation. "This partnership aligns seamlessly with our commitment to providing our customers with the latest and most advanced tools in the CNC and automation industry. Achteck's reputation for quality and innovation perfectly complements our mission."  Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck Tool Technology Co., Ltd. specializes in the development and production of high-performance cutting tools designed for precision machining applications. Achteck has developed products covering turning, milling and drilling technologies for all types of materials including steel, stainless steel, cast iron, aluminum alloy, super alloy and harden steel. With a focus on turning, milling and drilling carbide insert technological advancement and customer satisfaction, Achteck's tools are renowned for their durability, precision, and efficiency. As exclusive representatives, JMI CNC Tooling & Automation will play a pivotal role in introducing Achteck's cutting-edge products in the U.S. market, offering comprehensive support and expertise to manufacturers seeking to elevate their machining capabilities. This collaboration signifies a shared commitment to driving innovation and excellence within the CNC tooling and automation industry. Manufacturers can expect to benefit from an expanded range of solutions that enhance productivity, efficiency, and overall machining performance. About JMI CNC Tooling & Automation

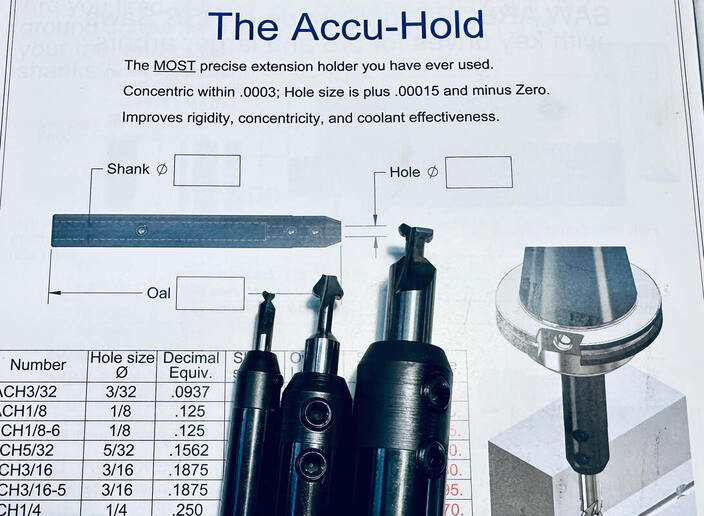

JMI CNC Tooling & Automation, also known as, Jones Marketing Inc. is a leading provider of CNC tooling and automation solutions. With a commitment to excellence, JMI delivers cutting-edge products and unparalleled service to industrial distributor and machine tool builders and dealers and manufacturers across various industries. About Achteck America Achteck Tool Technology Co., Ltd. is a global leader in the design and manufacturing of high-performance cutting tools. With a focus on innovation and precision, Achteck delivers advanced solutions that meet the evolving needs of the machining industry. When you're up against a wall and accuracy is critical and your'e cursing the design engineer, the Accu-Hold is THE tool the grizzled old machinists brings over and hands to you before he walks away smiling. written by Bernard Martin JMI Tooling & Automation proudly introduces A.B. Tool's Accu-Hold Extension Holders – hailed as the most precise extension holders in the industry. These innovative tools have set the bar very high for accuracy and ROI in machining applications that require small diameter precision. Unprecedented Precision: A Cut Above the Rest The hallmark feature of A.B. Tool's Accu-Hold Extension Holders lies in their unparalleled precision. The shanks and inside diameters of these extension holders boast coaxial perfection, achieving an impressive concentricity within .0003". This extraordinary level of precision has been meticulously measured using a .0001" indicator, employing a nominal gage pin projected 1/2” from the end of the holder.  When you're up against a wall The Accu-Hold is Ideally suited for those operations where you need to get close to a wall: Collet chucks won't work and end mill holders have too much runout, especially for small diameter cutting tools. That's why you sometimes find an Accu-Hold hidden away in the back of the old machinists Gerstner box. It's a "solution" tool! It's what you need when you need it! The precision achieved by Accu-Hold Extension Holders not only surpasses industry standards but more importantly improves surface finish and puts the "precision" in precision machining. This level of accuracy ensures that every cutting tool used with these extension holders operates with the least amount of runout! Coolant Access Accu-Hold Extension Holders provide superior coolant access to the tools. Effective coolant delivery is crucial in preventing heat buildup and ensuring the longevity of cutting tools. Accu-Hold Extension Holders facilitate efficient coolant flow, especially when dealing with smaller tools, thus contributing to a more sustainable and productive machining process. Successful Applications Redefining Industries

The Accu-Hold Extension Holders from A.B. Tool have demonstrated remarkable success across various applications including:

Elevating Precision, Redefining Possibilities A.B. Tool's Accu-Hold Extension Holders marks a significant milestone for every machinist in the pursuit of precision in machining. It's one of those tools that fix a problem that no one knew how to solve. You need one in your tool box. Mark it while you make it with Tapmatic's TapWriter and eliminate secondary operations! compiled and written by Bernard Martin Eliminating the need for secondary marking operations, Tapmatic's TapWriter is a CNC marvel that scribes numbers, text, date codes, or artwork directly onto your workpiece. This innovative dot-marking tool operates without spindle rotation, making it a versatile and efficient addition to your machining process.

Utilizing a long-life carbide stylus or a ballpoint, the TapWriter effortlessly creates fine lines on your workpiece. What sets it apart is its ability to mark curved surfaces without requiring adjustments to the Z-axis, offering precision without compromise. Part numbers, serial numbers, date codes, and even logos can be effortlessly etched onto your materials, whether they are soft or hard, with a hardness of up to 62 HRC. This adaptability makes the TapWriter an indispensable tool for various industries. Installation is a breeze as the TapWriter seamlessly integrates with machining centers or CNC lathes equipped with live tooling. It employs standard engraving software, eliminating the need for delicate cutting tools and high-speed spindles, streamlining your workflow. The TapWriter's versatility extends to the materials it can mark. Whether it's soft plastics or hardened steel up to 55 RC, its durable carbide stylus ensures a precise mark, even on uneven or rounded surfaces. Speed is a defining characteristic of the TapWriter, boasting a remarkable capacity of up to 80 characters per minute, contingent on your machine's capabilities. Its efficiency makes it a favored choice in the aerospace industry, where gentle curves in the dot's cross-section prevent stress concentration. With the TapWriter, you are in control of every aspect of your mark, from revolutions per minute dictating dots per minute to the velocity of the carbide stylus when it impacts your workpiece. It's time to take the hassle out of marking and embrace the precision, efficiency, and control offered by Tapmatic's TapWriter. Join Jones Marketing at SOUTHTEC 2023 - October 24-26, 2023! We're a premier Manufacturers' Representative Agency will be featuring innovative metal cutting technologies from a distinctive group of high performance tooling & workholding suppliers. Some with no known competitors! The Southeast is experiencing exceptional growth in areas critical to the economy, such as aerospace, automotive, advanced materials and workforce development – making the region a hotbed for advanced manufacturing. SOUTHTEC is designed to give manufacturers the means to discover and acquire the tools needed to drive the next evolution of their industry. SOUTHTEC creates a greater opportunity to engage first-hand with world-class suppliers and identify solutions needed – from development to final production. Save the date for SOUTHTEC 2023 - October 24-26, 2023. JMI's Booth will feature:

And don't forget to visit our other partners while you're at the show! You can click the links below to add them to your show planner: SOUTHTEC 2023 Details

Talk to us about!

|

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed