|

The article provides an in-depth look at MAQ's advancements in machining technology, particularly focusing on their innovative turning tool holders equipped with proprietary dampening technology. Ahmed Bousmina, a Mechanical Engineer at MAQ, offers insights into how these tools enhance efficiency and precision in the machining process. The discussion covers various aspects, including the versatility of tool designs, the significance of material choices, and the company's future directions. by Mariah Hellman

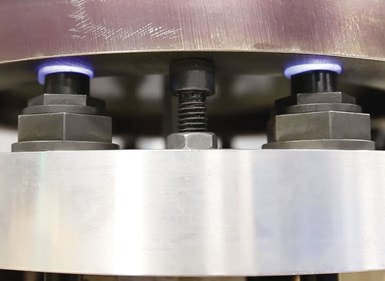

In an industry where precision and efficiency is paramount, MAQ has positioned themselves at the forefront of machining technology. Ahmed Bousmina, Mechanical Engineer at MAQ, sheds light on how the company is revolutionizing the machining process with its innovative tooling solutions, particularly focusing on turning tool holders equipped with proprietary dampening technology to combat harmful vibrations during machining. Innovating for efficiency and flexibility At the heart of MAQ’s product line are the turning tool holders, designed to accommodate a range of operational lengths and diameters, ensuring versatility for various machining tasks. “Our tools are categorized to simplify selection for our customers, focusing on the diameter and operational length rather than the total length of the tool, which is often irrelevant to the buyer,” Ahmed explains. This user-centric approach underscores MAQ’s commitment to providing solutions that genuinely meet the needs of operators and manufacturing professionals. Cutting-edge dampening technology What truly sets MAQ apart is the integration of dampening technology within their tool holders. This innovation significantly reduces vibrations that can compromise machining quality, allowing for smoother operations and higher precision. “We’ve divided our products into four main sections based on the tool’s diameter and the stick-out length, offering unparalleled performance across a wide range of specifications,” Ahmed says. Carbide reinforced and steel options When going into detail on the distinction between carbide-reinforced (CR) and full steel tool holders, Ahmed highlights how material choice is pivotal when machining at various lengths. “For longer tools where bending moments become a concern, carbide reinforcement on the tool’s back end ensures rigidity and optimal performance,” he noted. This nuanced understanding of material properties and machining dynamics is a testament to MAQ’s expertise and innovation in tool design. Modular and monoblock configurations MAQ offers tools in both modular and monoblock configurations, catering to different machining requirements. The modular system provides flexibility, allowing for head changes to accommodate various machining processes without the need for multiple tools. On the other hand, monoblock tools offer a rigid, integrated solution for specific applications. “This versatility ensures that our customers can achieve the best results with minimal tool changeover time,” Ahmed adds. Future directions and market expansion Looking ahead, MMAQ is focused on expanding its product range to provide for even more specialized needs. Already today, MAQ offers the widest range of products on the market, with the smallest tool measuring 6mm, and the largest up to 80mm in the standard range, while the capabilities span up to 350 millimeters in diameter and 5,5 meters in length. The technology is scalable, which enables everything from medical components requiring miniature precision to large-scale parts in the oil and gas or defense sectors. This, ensuring that MAQ’s technology is versatile enough to meet a broad spectrum of industry demands. Looking to the future, the goal is to expand the product range even more, to meet an even wider number of industries. “Our aim is to simplify machining worldwide, making it more efficient, precise, and cost-effective for our clients,” Ahmed concluded. With a relentless pursuit of innovation and a keen eye on the evolving needs of the machining industry, MAQ is not just a tool manufacturer – but a partner in machining excellence, paving the way for future advancements in the field.

0 Comments

JMI CNC Tooling & Automation Appointed Exclusive Manufacturers Representatives for Achteck America1/9/2024 Jones Marketing Inc to manage Southeastern region industrial supply chain and technical support for Achteck Tool Technology Co., Ltd. December, 2023 - JMI CNC Tooling & Automation, widely recognized as a leader in the CNC tooling and automation industry in the southeastern United States, is thrilled to announce their recent appointment as the exclusive manufacturers representatives for Achteck America. This strategic partnership marks a significant milestone for both JMI CNC Tooling & Automation and Achteck Tool Technology Co., Ltd., as it combines the strengths of two industry powerhouses to deliver cutting-edge solutions to the manufacturing sector. Achteck Tool Technology Co., Ltd., known for its innovation and precision in tool manufacturing, has selected JMI CNC Tooling & Automation as the exclusive representative for their products in the the Southeastern United States. This collaboration aims to enhance accessibility and technical support to Achteck's advanced tooling solutions, providing manufacturers with state-of-the-art technologies to optimize their machining processes. "We are honored and excited to be appointed as the exclusive manufacturers representatives for Achteck Tool Technology," said Kenneth Jones, President at JMI CNC Tooling & Automation. "This partnership aligns seamlessly with our commitment to providing our customers with the latest and most advanced tools in the CNC and automation industry. Achteck's reputation for quality and innovation perfectly complements our mission."  Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck Tool Technology Co., Ltd. specializes in the development and production of high-performance cutting tools designed for precision machining applications. Achteck has developed products covering turning, milling and drilling technologies for all types of materials including steel, stainless steel, cast iron, aluminum alloy, super alloy and harden steel. With a focus on turning, milling and drilling carbide insert technological advancement and customer satisfaction, Achteck's tools are renowned for their durability, precision, and efficiency. As exclusive representatives, JMI CNC Tooling & Automation will play a pivotal role in introducing Achteck's cutting-edge products in the U.S. market, offering comprehensive support and expertise to manufacturers seeking to elevate their machining capabilities. This collaboration signifies a shared commitment to driving innovation and excellence within the CNC tooling and automation industry. Manufacturers can expect to benefit from an expanded range of solutions that enhance productivity, efficiency, and overall machining performance. About JMI CNC Tooling & Automation

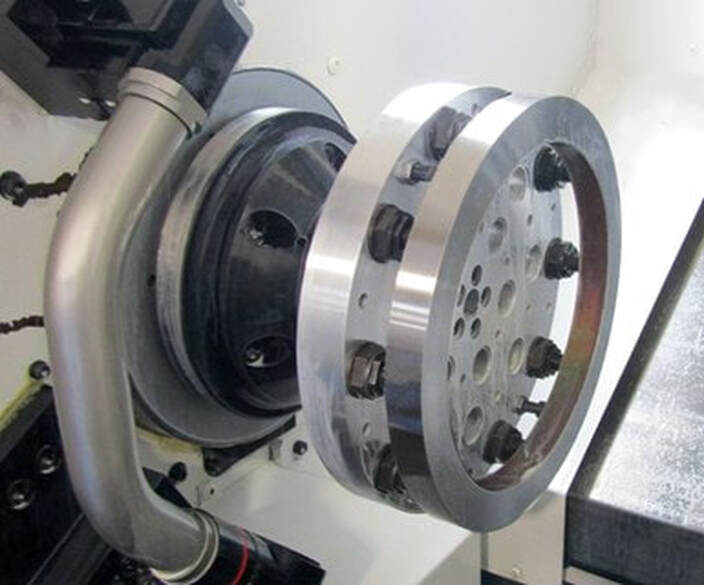

JMI CNC Tooling & Automation, also known as, Jones Marketing Inc. is a leading provider of CNC tooling and automation solutions. With a commitment to excellence, JMI delivers cutting-edge products and unparalleled service to industrial distributor and machine tool builders and dealers and manufacturers across various industries. About Achteck America Achteck Tool Technology Co., Ltd. is a global leader in the design and manufacturing of high-performance cutting tools. With a focus on innovation and precision, Achteck delivers advanced solutions that meet the evolving needs of the machining industry. Masa Tool, Inc. is a company founded with the mission of bringing micromachining solutions to industry. The Microconic™ work holding system is a mechanically actuated micro-workholding system for use in high precision, small diameter CNC turning applications. It's the first and only workholding system for the micro machining industry! What is "Microconic"?The name "Microconic" comes from the sophisticated grinding techniques that were developed for our collets. These techniques provide the advantages of extreme accuracy, high gripping force, and high tolerance for workpiece size differentials. Each finger of the collet has a separate conical surface that acts to apply the gripping force with superb accuracy. The Microconic system is a miniaturized, precision collet system that consists of two major components: the Microconic cartridge, which fits into your machine and transforms the work spindle for miniature work holding; and the Microconic collet, a "right-sized" collet that fits in the Microconic cartridge and is designed for superior performance with small workpieces, typically .0001" to .00015" (3 microns) concentricity, and guaranteed to be within 0.0002" (5 microns) in production use. The advantages of the Microconic cartridge

ABOUT: Indian Mountain Machine is committed to providing exceptional value through competitive pricing, superior quality, and dependable on-time deliveries as well as personal and professional customer service. Every year Indian Mountain Machine provides thousands of precision machined parts to companies of all sizes. They machine many types of materials including stainless, brass/bronze, copper, plastic, aluminum, epoxy, Delrin, nylon, PVC and carbon fiber. by Jerry McNealy, Owner, Indian Mountain Machine My name is Jerry McNealy – I’ve been in the machining industry for over thirty years, and I am the owner and operator of Indian Mountain Machine based out of Jellico, Tennessee. Here, we handle some highly complex and precision parts (most of which have just as high a value placed on their cosmetics as they do their function/tolerance). Pair this with the fact that I started running a CNC lathe only a couple years into my early career, and I can definitely claim to know a thing or two about some of the problems you tend to come across with thin-wall parts in a lathe. At our shop, we do several somewhat thin wall long parts, and we’ve bought other anti-vibe bars in the past that have usually resulted in having to turn the RPM down very low, as well as the feed rates, which results in these projects taking a considerable amount of time to achieve the finish we need – and it’s still not good enough. One day, we were tooling up another machine to do some parts, and I spoke with Gary McNealy at Jones Marketing Inc., who suggested that we try out this new chatter-free anti-vibe bar made by MAQ. I hadn’t yet heard of MAQ, but it looked interesting, and I trusted his recommendation. Looking back on it now, I’m extremely glad we did – because I have never seen anything perform quite as well as these bars do. We decided to start out with a 1” diameter bar, running some 6.5” long parts – which then progressed into some 8” long parts, and still only required a 1” diameter bar.

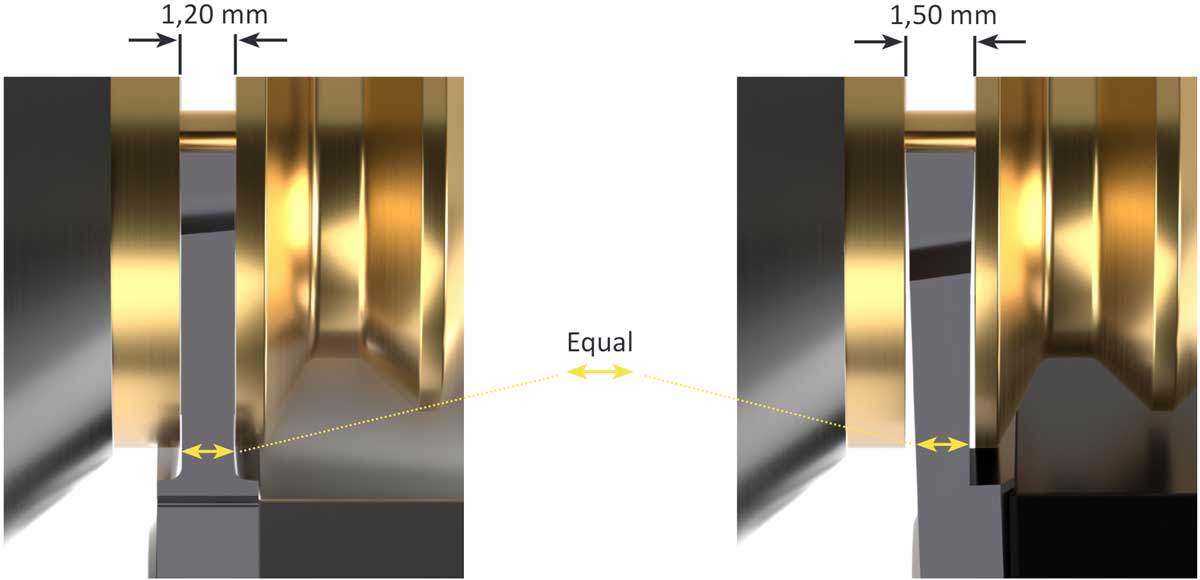

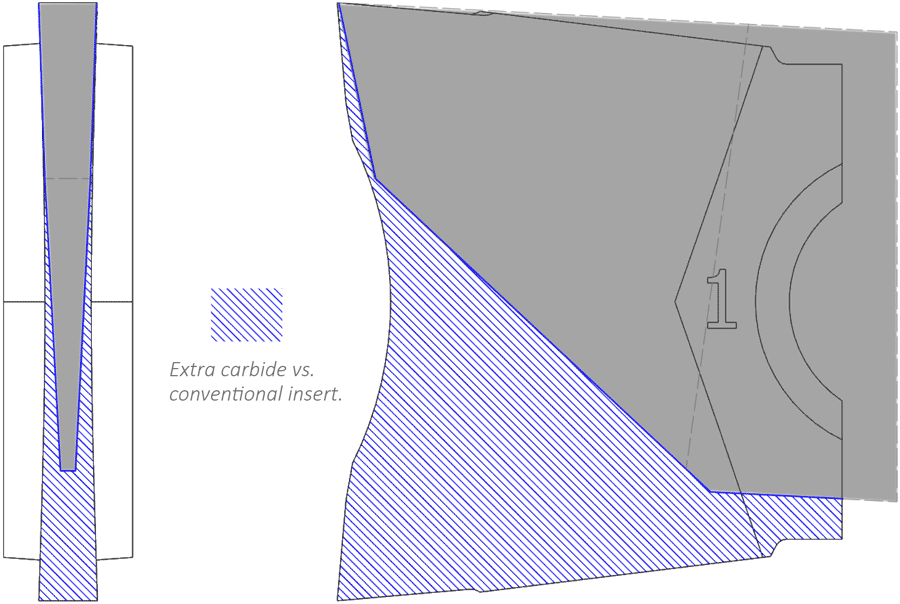

And as we continued to run parts, we kept increasing the speed and feed rate, before finally ending up around 1000 RPMs and a feed rate of .005 IPR. We were completely surprised by the finish, not to mention the speed with which we could now produce these parts! In fact, another incredible thing that the MAQ Bar’s performance has done is improve the product and its finish, allowing us to actually skip the dreaded sanding and polishing process. Some parts can even be cleaned and shipped straight to plating. We ended up going into some 9” long parts, which we were able to get the 1.25” bar for. To really illustrate how great the MAQ Bar is, though, when we first started running the parts, I went over to my toolbox and got the best 1.25” anti-vibe bar that we’d had previously, thinking that we might just try with it first and see how it goes. This bar has seen a lot of parts over the years, and it has a lot of character to show for it; rubber bands wrapped around it, bungee cords wrapped around the parts, the whole deal – anything to dampen vibration. Using this bar, however, we only ended up with what I figured to be a low RPM, slow speed, and a very poor finish. This particular part we were working on was going to take up to an hour and 15 minutes to rough and finish the bore. But once we switched over to the MAQ 1.25” Bar, it roughed and finished the part with the same bar in less than 15 minutes. The finished product was checking at under a 20 (micro), and was absolutely immaculate. Like I said, I’ve been at this a long time – and I’ve definitely been around the block enough to recognize a game-changer when I see it. MAQ Bars are, without a doubt, true standouts that have impressed me and the rest of the team here at Indian Mountain Machine. They are built to extremely high standards, save us valuable time, and are completely dependable, always resulting in final products that we are proud to ship out from our shop. I am personally a huge fan of MAQ, and I cannot recommend them highly enough. You will not be disappointed with what they have to offer. The power and strength is where it needs to be - times two. WhizCut has re-invented the parting off insert for the future. WhizTwin is a bold new insert that helps reduce waste material and has a cutting edge stability. The patent pending design of WhizTwin generates a cutting edge stronger than any other and a stability not seen before. The strength and increased stability of the cutting edge is maximised with two cutting edges at the front. This lets the toolholder be clamped in a more stable position with a smaller overhang from the toolholder plate - reducing instability and vibrations which are the main chal-lenges when parting off. Less material waste, less costs. WhizTwin is forceful, stable and overall brilliant. The narrow insert allows you to lower your production cost as you save material using it. Removing less bar material is great for you and also for the environ-ment. It’s a win win - with WhizTwin. Power up your parting off |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed