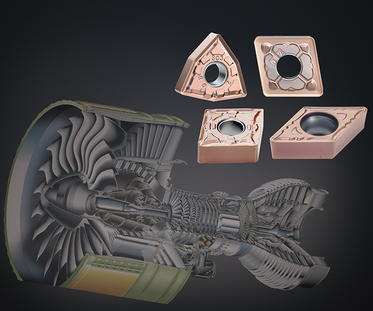

JMI CNC Tooling & Automation Appointed Exclusive Manufacturers Representatives for Achteck America1/9/2024 Jones Marketing Inc to manage Southeastern region industrial supply chain and technical support for Achteck Tool Technology Co., Ltd. December, 2023 - JMI CNC Tooling & Automation, widely recognized as a leader in the CNC tooling and automation industry in the southeastern United States, is thrilled to announce their recent appointment as the exclusive manufacturers representatives for Achteck America. This strategic partnership marks a significant milestone for both JMI CNC Tooling & Automation and Achteck Tool Technology Co., Ltd., as it combines the strengths of two industry powerhouses to deliver cutting-edge solutions to the manufacturing sector. Achteck Tool Technology Co., Ltd., known for its innovation and precision in tool manufacturing, has selected JMI CNC Tooling & Automation as the exclusive representative for their products in the the Southeastern United States. This collaboration aims to enhance accessibility and technical support to Achteck's advanced tooling solutions, providing manufacturers with state-of-the-art technologies to optimize their machining processes. "We are honored and excited to be appointed as the exclusive manufacturers representatives for Achteck Tool Technology," said Kenneth Jones, President at JMI CNC Tooling & Automation. "This partnership aligns seamlessly with our commitment to providing our customers with the latest and most advanced tools in the CNC and automation industry. Achteck's reputation for quality and innovation perfectly complements our mission."  Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck's PCD Coated AP100S insert grade has excelled in testing in stainless steel & hi-temp alloys. Contact JMI to run some test inserts. Achteck Tool Technology Co., Ltd. specializes in the development and production of high-performance cutting tools designed for precision machining applications. Achteck has developed products covering turning, milling and drilling technologies for all types of materials including steel, stainless steel, cast iron, aluminum alloy, super alloy and harden steel. With a focus on turning, milling and drilling carbide insert technological advancement and customer satisfaction, Achteck's tools are renowned for their durability, precision, and efficiency. As exclusive representatives, JMI CNC Tooling & Automation will play a pivotal role in introducing Achteck's cutting-edge products in the U.S. market, offering comprehensive support and expertise to manufacturers seeking to elevate their machining capabilities. This collaboration signifies a shared commitment to driving innovation and excellence within the CNC tooling and automation industry. Manufacturers can expect to benefit from an expanded range of solutions that enhance productivity, efficiency, and overall machining performance. About JMI CNC Tooling & Automation

JMI CNC Tooling & Automation, also known as, Jones Marketing Inc. is a leading provider of CNC tooling and automation solutions. With a commitment to excellence, JMI delivers cutting-edge products and unparalleled service to industrial distributor and machine tool builders and dealers and manufacturers across various industries. About Achteck America Achteck Tool Technology Co., Ltd. is a global leader in the design and manufacturing of high-performance cutting tools. With a focus on innovation and precision, Achteck delivers advanced solutions that meet the evolving needs of the machining industry.

0 Comments

Via MAQ Tool. Grooving has always been a challenging machining task, both for internal and external machining, due to its vibrations. Particularly for internal grooving operations, the feed force is aligned to the radial direction of the tool, and that excites substantial vibrations in the tool holder. Traditionally the recommendation is to use a steel damped bar for grooving operations above 5xD and a carbide-reinforced damped bar for operations 6-7xD. Above 7xD it has earlier been nearly impossible to do grooving. Thanks to MAQ, it’s now possible to do grooving operations up to 8xD! Using an STMD M25-255 product which is a standard steel bar damped with the STMD technology, with an SXFNR 251724 16 cutter head and 16 IR W 2.25 insert, we perform grooving at 8xD overhang length. Machining in alloyed steel of 4340 HRC 28-30, the grooving process was smooth and quiet. Thanks to the STMD technology, with its Self-Tuning capabilities, the tool adapts to different types of vibrations, and the limits are again pushed by MAQ. Need to make a shallow groove for an O-ring seat or retaining rings? The standard selection of 16mm trigonal grooving inserts can help you make grooves with a max depth of 2.25mm. The width can be widened by a longitudinal turning operation.

Our mission is to bring new technology to the workshops to make things better, faster, and easier. “Simplify Machine” in other words! |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed