|

Breakage, Wobble and Rubbing problems are often caused by how the washers are mounted on either side of saw. compiled & edited by Bernard Martin It's commonly known that when saw thickness is less than 0.125″, keyways can cause stress risers and cracks. That is why washers are often used. However, Breakage, Wobble and Rubbing problems are often caused by how the washers are mounted on either side of saw.

Remember, washers drive the saw in the absence of a drive key. They must always be clean, flat and bur-free. A speck of dirt will let saws wobble and cut oversize. If a saw breaks, it may score the washers. Always check for scoring marks around saw hole for dirt, chips or grit. Shiny spots, as small as a pinpoint, indicate that chips where imbedded under washers. Circular skid marks indicate the nut was not tight. Generally speaking:

Saw Blade Teeth most often break as a result of:

NOTE: HSS saws will turn colors as they heat during cutting. A straw color is the limit. The saw will lose its temper when it starts turning blue.

0 Comments

Jack Rushlander, Jergens Technical Sales Manager discusses layout and planning techniques for 5-axis machining centers. Jack Rushlander from Jergens workholding talks about how advancements in 5 Axis CNC machining technology has changed dramatically in the past 20 years. Dynamic Work Offsets and other capabilities have made workholding easier but also given shops even more opportunities to to improve process and reduce cycle time. Check out the video below and see how Galactic Widget Company tackles the workholding of a Thingamajig.

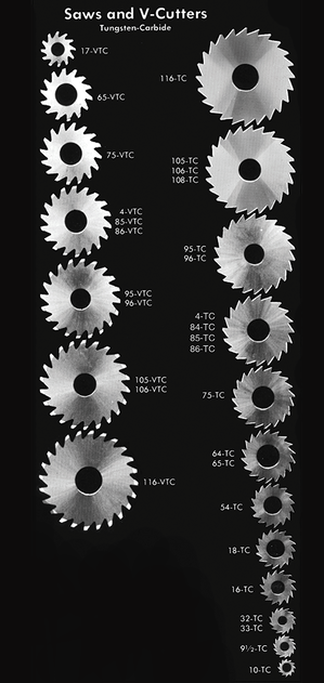

compiled & edited by Bernard Martin As more and more of our customers are using Martindale Gaylee Circular saws we put together this guide to the commonly asked questions such as "Is there a rule-of-thumb for the number of teeth?" or "How much side clearance should I have?" Here we cover a lot of the fundamentals of selecting the right circular saw blade configuration, some tips, tricks, and troubleshooting for when things go wrong. Circular Saw Feed RatesThese are general cutting speed recommendations for circular saws used in metalcutting from Martindale/Gaylee. The may vary from application to application but are basically some general suggestions starting parameters when using high speed or carbide saws.

Selecting the Proper Number of Teeth in Your Metalcutting SawGenerally speaking, deep cuts and soft material require fewer teeth for chip clearance and stronger teeth (landed). Thin material requires more teeth, but keep-in-mind that at least 2 teeth on the blade need to be engaged in cut. Hard materials and narrow slots (under .025”) likewise require more teeth. Hard Materials require more teeth, and give a smoother cut, but at a much lower production rate. Alternately beveled teeth keep chips from sticking in the cut and in the tooth gullets. And Remember that there should be at least 2 teeth engaged in the cut at all times.

Rake Angles and |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed