|

Join Jones Marketing at SOUTHTEC 2023 - October 24-26, 2023! We're a premier Manufacturers' Representative Agency will be featuring innovative metal cutting technologies from a distinctive group of high performance tooling & workholding suppliers. Some with no known competitors! The Southeast is experiencing exceptional growth in areas critical to the economy, such as aerospace, automotive, advanced materials and workforce development – making the region a hotbed for advanced manufacturing. SOUTHTEC is designed to give manufacturers the means to discover and acquire the tools needed to drive the next evolution of their industry. SOUTHTEC creates a greater opportunity to engage first-hand with world-class suppliers and identify solutions needed – from development to final production. Save the date for SOUTHTEC 2023 - October 24-26, 2023. JMI's Booth will feature:

And don't forget to visit our other partners while you're at the show! You can click the links below to add them to your show planner: SOUTHTEC 2023 Details

Talk to us about!

0 Comments

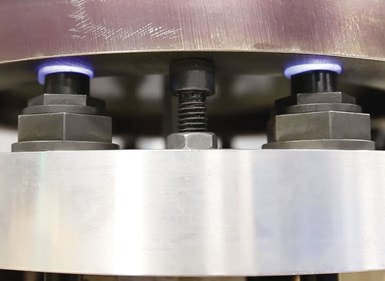

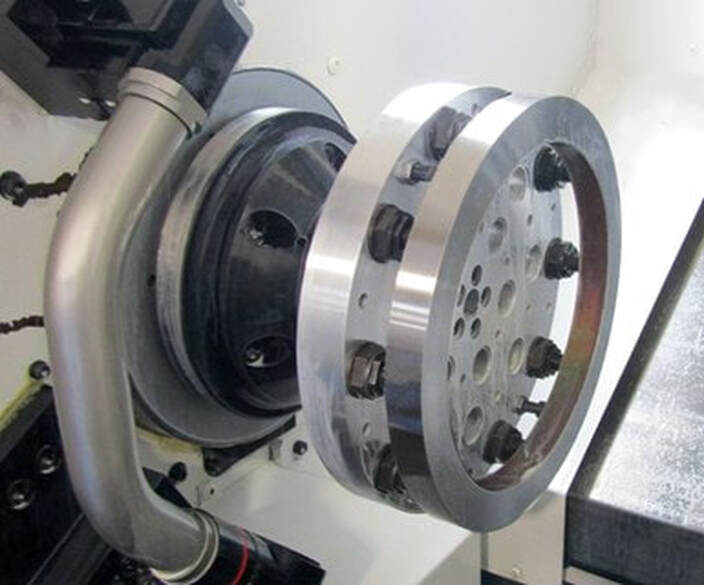

Blue Photon's “Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.” by DEREK KORN | Editor-in-Chief, Production Machining Magazine For some turning applications, chuck jaws or other conventional workholding devices for CNC lathes can cause a part to distort as clamping force is applied. This can be the case for large, thin rings such as the one shown on the left. Those workholding elements can also prevent full access to a part, which might necessitate reclamping for an additional operation.  After cleaning grippers with isopropyl alcohol, adhesive is deposited on each on After cleaning grippers with isopropyl alcohol, adhesive is deposited on each on Blue Photon offers an alternate workholding method for these types of situations that uses adhesive cured by ultraviolet (UV) light to secure a part for turning. It can also be used for other processes such as milling, grinding, electrical discharge machining and 3D printing/additive manufacturing. The primary components for the company’s photoactivated adhesive system are a UV light source with a light guide, BlueGrip adhesive and UV light-transmitting grippers that serve as lenses through which the UV light passes to cure the adhesive and bond a part to a fixturing element.  Hard stops, such as Allen bolts are used to provide the proper adhesive gap between grippers and part. Hard stops, such as Allen bolts are used to provide the proper adhesive gap between grippers and part. The threaded grippers install in the top of a fixture plate and require a through-hole to enable the UV light to pass up and through the gripper to cure the adhesive. For most turning applications, this would be done at a workstation and the fixture plate with bonded part would then be installed on the lathe. To do this, the top of each gripper and the areas of the part to be gripped are cleaned with isopropyl alcohol. Adhesive is deposited on the top of each gripper so that the entire gripper face is covered and the gap between the face and underside of the part is filled. The gaps (thus, the thickness of the adhesive) can range from 0.020 to 0.120 inch, depending on part flatness. The part rests on hard stops installed in the fixture plate that are slightly taller than the gripper tops to achieve the proper gap.  With the fixture removed from the machine, a wrench is used to back off each gripper and break the bond with the part. With the fixture removed from the machine, a wrench is used to back off each gripper and break the bond with the part. To cure the adhesive, the UV light source’s light guide is inserted into the backside of each gripper and the source is activated. It typically takes 60 to 90 seconds for the UV light to cure the adhesive, bonding the gripper to the part. Once curing is complete for all grippers, the fixturing element with the part can be installed in the machine and machining can be performed. Once machining is completed, a wrench is used to back off each threaded gripper, shearing the adhesive bond with the part. The residual adhesive can then be peeled off the part and grippers after applying steam, or a hot water soak or spray. The number of required grippers is based on the size of the part and its geometry, the company says. Axial holding force depends on gripper size and can range from 250 to 800 pounds. Grippers are made from hardened, corrosion-resistant stainless steel and have a black oxide finish. The adhesive is compatible with most water- and oil-based coolants and cutting fluids. It is said to be able to hold a variety of ferrous and nonferrous metals as well as plastics, ceramics and composite materials. |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed