|

Edited by Bernard Martin Often times in a shop, a saw arbor is a saw arbor is a saw arbor. That's just not the case and Martindale Gaylee offers several solutions. They have variants to saw arbors to meet your specific needs whether it be in a CNC milling machine, a CNC Lathe, a manual mill or even a Swiss Style CNC machine. This includes:

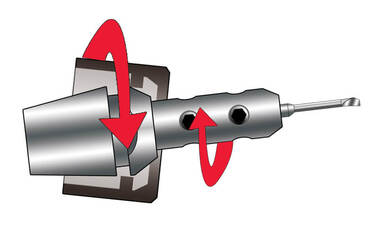

Let's take a look at the differences below. TI-LOC® Saw Arbors with integrated ER taperThe Ti-Loc® SwissClamp System is a taper-integrated small tooling system is designed to work with virtually any collet or tool holder that employs the ER collet system (DIN6499). The Ti-Loc directly mounts into ANY ER Taper Live or Static Tool Position. The Ti-Loc® System works with any existing tool holder and most all ER collet clamping nuts. Simply insert the Ti-Loc holder into any ER nut and twist to align the locking cam profile jus was you would for any ER collet. The Ti-Loc® SwissClamp System can be used in any machine that has ER collet live tooling. It comes standard with ER 11, ER16 and ER20 taper arbors that serve as their own collet, eliminating need for two-piece arbor system. This single piece design adds rigidity of set-up and improves total indicated runout (TIR). In fact, it reduces tolerance “stacking” to an incredibly low TIR of less than 0.0002". To top it off, it's less expensive & more cost effective than most comparable two-piece arbor systems. A recommended maximum saw thickness is approximately 0.080” Gold Star Precision Series |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed