|

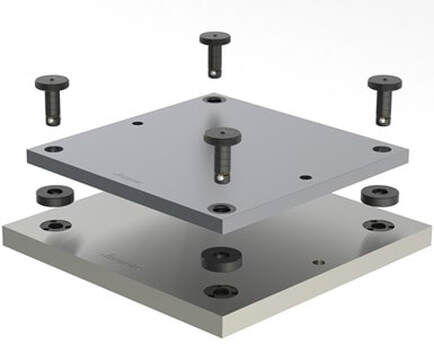

Jergens Inc. offers fixture plate machining kits and receiver bushing plugs for its line of Ball Lock quick-change mounting systems. EDITED BY JEDD COLE Production Editor, Modern Machine Shop Jergens Inc. offers fixture plate machining kits and receiver bushing plugs for its line of Ball Lock quick-change mounting systems.  The machining kits consist of one fixture plate, four extra-long Ball Lock shanks and four spacers that provide clearance between the fixture plate and subplate below. This open space allows cutting tools to “break through” the fixture plate without damaging the subplate, making it possible to machine fixture plates while mounted to the same subplates they will be used with during production, the company says. The plugs are designed to prevent chips and coolant from accumulating inside receiver bushings that are not in use during certain operations. This saves time by eliminating the need to clean out the bushings between setups. The receiver plugs are made of blue anodized aluminum, providing durability for better resistance to hot chips when compared to plastic plugs. The flush mount design means the plugs do not protrude above the subplate surface, making it easier to clean and avoiding interference during machining. These plugs are available in standard sizes to accommodate different hole openings and come with an O ring and tapped hole for easy installation.

0 Comments

|

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed