|

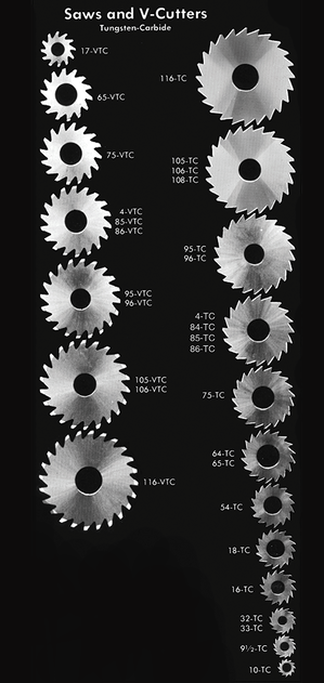

compiled & edited by Bernard Martin As more and more of our customers are using Martindale Gaylee Circular saws we put together this guide to the commonly asked questions such as "Is there a rule-of-thumb for the number of teeth?" or "How much side clearance should I have?" Here we cover a lot of the fundamentals of selecting the right circular saw blade configuration, some tips, tricks, and troubleshooting for when things go wrong. Circular Saw Feed RatesThese are general cutting speed recommendations for circular saws used in metalcutting from Martindale/Gaylee. The may vary from application to application but are basically some general suggestions starting parameters when using high speed or carbide saws.

Selecting the Proper Number of Teeth in Your Metalcutting SawGenerally speaking, deep cuts and soft material require fewer teeth for chip clearance and stronger teeth (landed). Thin material requires more teeth, but keep-in-mind that at least 2 teeth on the blade need to be engaged in cut. Hard materials and narrow slots (under .025”) likewise require more teeth. Hard Materials require more teeth, and give a smoother cut, but at a much lower production rate. Alternately beveled teeth keep chips from sticking in the cut and in the tooth gullets. And Remember that there should be at least 2 teeth engaged in the cut at all times.

Rake Angles and |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed