|

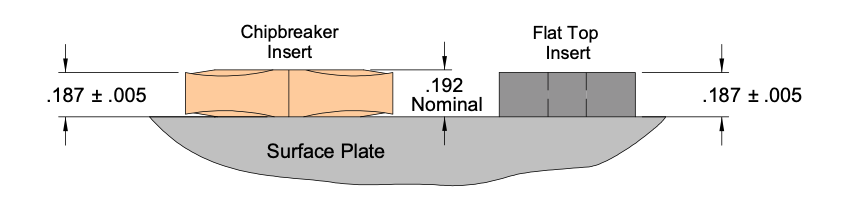

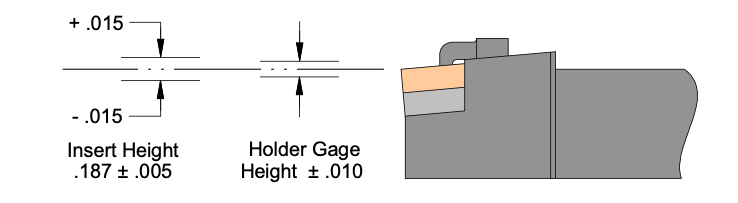

by Charles Colerich for Horizon Carbide The Industry Standard thickness tolerance for “G” (ground) and “M” (molded) class Inserts is ± .005. This standard was established before the introduction of molded chipbreakers and creates confusion regarding double sided turning Inserts. Negative rake chipbreaker Inserts are nominally thicker than flat top Inserts. An elevated pad on both sides of the Inserts keep the unused edges from contacting the tool holder or shim seat. The tolerance refers to the cutting edge height rather than the Insert thickness. The easiest way to measure the cutting edge height is with a height gage on a surface plate. Tool Holder Insert HeightThe Industry Standard for Insert height in tool holders is ± .010. This creates a Center Height range of .030 (± .015) when combined with the Insert tolerance of ± .005. For best results on smaller diameter parts and/or small nose radius Inserts the center height should be adjusted to a maximum of ± .001. Insert Cutting Edge HeightInsert heights for most negative rake tool holders are set using .031R Gage Inserts.

There are no geometry standards for negative rake 35° tool holders. Insert rake angles vary between manufacturers and range from -6° to -13°. This causes problems with inserts having a nose radius other than .031R. Center Heights for smaller radius inserts drop due to the negative rake angles. The drop is significant with 35° and 55° Negative Rake inserts. Horizon DNGP and VNGP Inserts are ground to the low side of the height tolerance to reduce center height problems.

0 Comments

Leave a Reply. |

BREAKING NEWSCheck the category list below for your subject of interest. We bring you the latest breaking news and tech tips here! Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed