|

Masa Tool, Inc. is a company founded with the mission of bringing micromachining solutions to industry. The Microconic™ work holding system is a mechanically actuated micro-workholding system for use in high precision, small diameter CNC turning applications. It's the first and only workholding system for the micro machining industry! What is "Microconic"?The name "Microconic" comes from the sophisticated grinding techniques that were developed for our collets. These techniques provide the advantages of extreme accuracy, high gripping force, and high tolerance for workpiece size differentials. Each finger of the collet has a separate conical surface that acts to apply the gripping force with superb accuracy. The Microconic system is a miniaturized, precision collet system that consists of two major components: the Microconic cartridge, which fits into your machine and transforms the work spindle for miniature work holding; and the Microconic collet, a "right-sized" collet that fits in the Microconic cartridge and is designed for superior performance with small workpieces, typically .0001" to .00015" (3 microns) concentricity, and guaranteed to be within 0.0002" (5 microns) in production use. The advantages of the Microconic cartridge

0 Comments

ABOUT: Indian Mountain Machine is committed to providing exceptional value through competitive pricing, superior quality, and dependable on-time deliveries as well as personal and professional customer service. Every year Indian Mountain Machine provides thousands of precision machined parts to companies of all sizes. They machine many types of materials including stainless, brass/bronze, copper, plastic, aluminum, epoxy, Delrin, nylon, PVC and carbon fiber. by Jerry McNealy, Owner, Indian Mountain Machine My name is Jerry McNealy – I’ve been in the machining industry for over thirty years, and I am the owner and operator of Indian Mountain Machine based out of Jellico, Tennessee. Here, we handle some highly complex and precision parts (most of which have just as high a value placed on their cosmetics as they do their function/tolerance). Pair this with the fact that I started running a CNC lathe only a couple years into my early career, and I can definitely claim to know a thing or two about some of the problems you tend to come across with thin-wall parts in a lathe. At our shop, we do several somewhat thin wall long parts, and we’ve bought other anti-vibe bars in the past that have usually resulted in having to turn the RPM down very low, as well as the feed rates, which results in these projects taking a considerable amount of time to achieve the finish we need – and it’s still not good enough. One day, we were tooling up another machine to do some parts, and I spoke with Gary McNealy at Jones Marketing Inc., who suggested that we try out this new chatter-free anti-vibe bar made by MAQ. I hadn’t yet heard of MAQ, but it looked interesting, and I trusted his recommendation. Looking back on it now, I’m extremely glad we did – because I have never seen anything perform quite as well as these bars do. We decided to start out with a 1” diameter bar, running some 6.5” long parts – which then progressed into some 8” long parts, and still only required a 1” diameter bar.

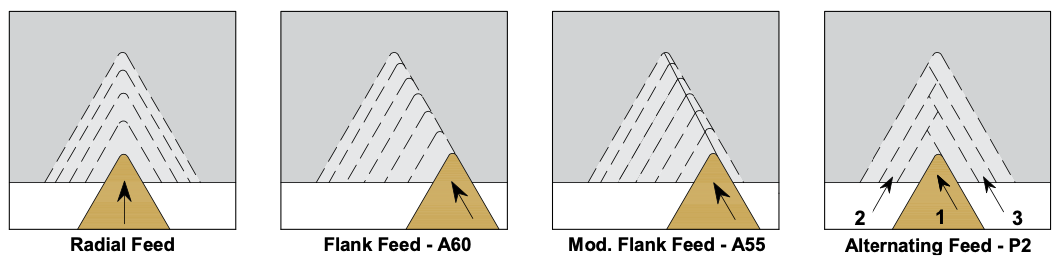

And as we continued to run parts, we kept increasing the speed and feed rate, before finally ending up around 1000 RPMs and a feed rate of .005 IPR. We were completely surprised by the finish, not to mention the speed with which we could now produce these parts! In fact, another incredible thing that the MAQ Bar’s performance has done is improve the product and its finish, allowing us to actually skip the dreaded sanding and polishing process. Some parts can even be cleaned and shipped straight to plating. We ended up going into some 9” long parts, which we were able to get the 1.25” bar for. To really illustrate how great the MAQ Bar is, though, when we first started running the parts, I went over to my toolbox and got the best 1.25” anti-vibe bar that we’d had previously, thinking that we might just try with it first and see how it goes. This bar has seen a lot of parts over the years, and it has a lot of character to show for it; rubber bands wrapped around it, bungee cords wrapped around the parts, the whole deal – anything to dampen vibration. Using this bar, however, we only ended up with what I figured to be a low RPM, slow speed, and a very poor finish. This particular part we were working on was going to take up to an hour and 15 minutes to rough and finish the bore. But once we switched over to the MAQ 1.25” Bar, it roughed and finished the part with the same bar in less than 15 minutes. The finished product was checking at under a 20 (micro), and was absolutely immaculate. Like I said, I’ve been at this a long time – and I’ve definitely been around the block enough to recognize a game-changer when I see it. MAQ Bars are, without a doubt, true standouts that have impressed me and the rest of the team here at Indian Mountain Machine. They are built to extremely high standards, save us valuable time, and are completely dependable, always resulting in final products that we are proud to ship out from our shop. I am personally a huge fan of MAQ, and I cannot recommend them highly enough. You will not be disappointed with what they have to offer. by Charles Colerich for Horizon Carbide Here are four guidelines to help improve your threading process when threading on a lathe. 1. Start Near the top of the SFM rangeAs a good rule of thumb, always start near the top of the Surface Foot per Minute Range for the material that is being threaded. Higher SFM reduces Built-up Edge, the major cause of poor tool life in threading. For Harder or more Abrasive Materials start in the Middle of the SFM range. Once setup is complete SFM can be adjusted for optimum tool life. Tough Micrograin Grade 310 reduces insert chipping from edge build-up at lower SFM and on parts under 1” Diameter. Formulas to calculate Revolutions Per Minute (RPM) and Surface Feet Per Minute (SFM) : RPM = SFM x 12 Divided by Part Diameter x 3.1416 SFM = 3.1416 x Part Diameter, Divided by 12 x RPM 2. Use the G76 Threading CycleAs a second good rule of thumb, use the G76 Threading cycle with Fanuc, Yasac and similar CNC controllers. If P1, P2, P3, & P4 parameters are available, use P1 for most applications. G76 - P1 removes equal amounts of material with every pass. P2 alternates between front & back cutting edges and should only be used on 6 tpi & coarser threads. 3. Set Depth of Cut for the 1st Pass at 20% - 30%Set the Depth of Cut (DOC) for the first past at 20-30% of the thread height per side. G76 controls the depth of cut for the remaining passes. To find the DOC for the 1st Pass multiply the PITCH by 0.6 to get the approximate THREAD HEIGHT. Multiply THREAD HEIGHT by 20 - 30% to get the DEPTH of the 1st Pass. Use less than 20% when threading hard materials or larger thread pitches. Do not use “Spring Passes” under .002 DOC Per Side. EXAMPLE: CALCULATING THE DOC FOR THE FIRST PASS ON A 1/2-20 THREAD 1” 20 =.050PITCH),(.050x.6 =.030 (THREADHEIGHT), .030x.3 =.009 (DEPTHOF1stPASS 4. Use the A55 Parameter to set the Infeed AngleMost CNC Lathe Controls offer a choice of A60, A55, A30 & A29. A60 is the default setting. A55 is equivalent to setting the compound feed on a manual lathe to 27.5°. In most applications A55 will double or triple tool life over A60.

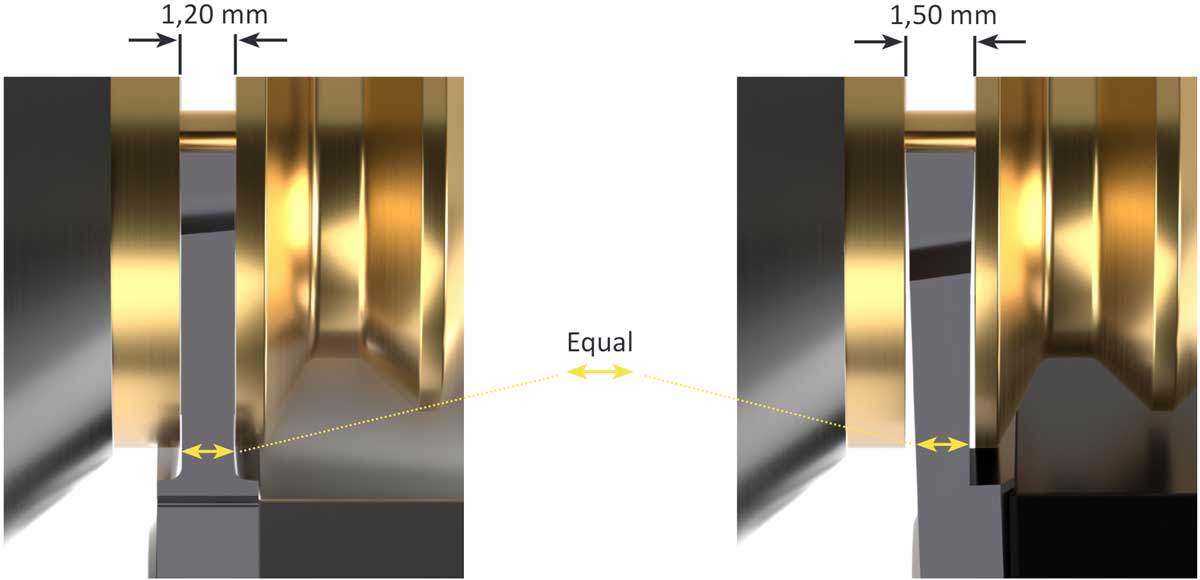

The power and strength is where it needs to be - times two. WhizCut has re-invented the parting off insert for the future. WhizTwin is a bold new insert that helps reduce waste material and has a cutting edge stability. The patent pending design of WhizTwin generates a cutting edge stronger than any other and a stability not seen before. The strength and increased stability of the cutting edge is maximised with two cutting edges at the front. This lets the toolholder be clamped in a more stable position with a smaller overhang from the toolholder plate - reducing instability and vibrations which are the main chal-lenges when parting off. Less material waste, less costs. WhizTwin is forceful, stable and overall brilliant. The narrow insert allows you to lower your production cost as you save material using it. Removing less bar material is great for you and also for the environ-ment. It’s a win win - with WhizTwin. Power up your parting off |

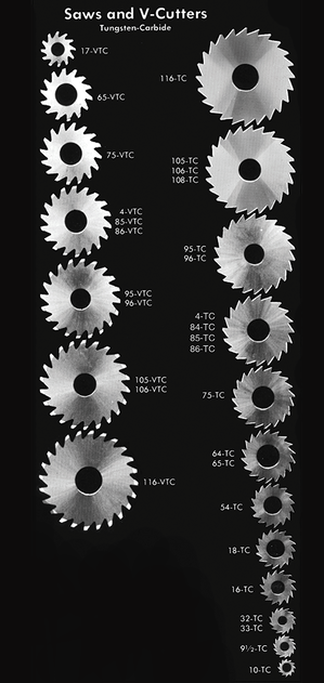

| Increase Number of Teeth For:

Decrease Number of Teeth For:

|

Rake Angles and

Side Clearance Angles

Just as in an end mill or a band saw blade, a rake angle is the term used to describe the direction of the blade’s teeth, as referenced from the rotation and central axis of a saw blade. If you imagine a line going from the exact center of the blade to each tooth, having the front of the tooth directly on that line would be a zero degree rake angle. The rake angle of the blade is described in comparison to that imaginary line.

A positive rake angle meana that the teeth are angled more towards the angle of rotation, while a negative rake angle would mean that they are angled backwards, away from the direction of rotation. Generally speaking, the preferred rake angle is:

- 5° to 10° positive for other soft materials.

- 5° negative for yellow brass

- On center for steel.

SIDE CLEARANCE (Tangential Clearance Angle)

This is also known as dish or hollow grind. You measure down the side of the tip and the difference it is the difference between front and back. As you cut, material it gets compressed and springs back after the cutting edge passes.

A steep side clearance angle gives plenty of room for the material to expand and prevents thermal expansion of the base material. Keep in mint that a very flat side clearance angle can provide a smoother cut in some materials. For stainless steel and tenacious metals such as copper, zinc, tin or lead an increase in the side clearance is desirable as these materials tend to "spring back" (thermal expansion) on the blade.

BREAKING NEWS

Check the category list below for your subject of interest. We bring you the latest breaking news and tech tips here!

Categories

All

AB Tool

Accu-Hold

Achteck

Achteck AP100S

Arbor: Custom

Arbor: Gold Star

Arbor: Ti-Loc Swiss

Balance Systems

BlueGrip Adhesive

Blue Photon

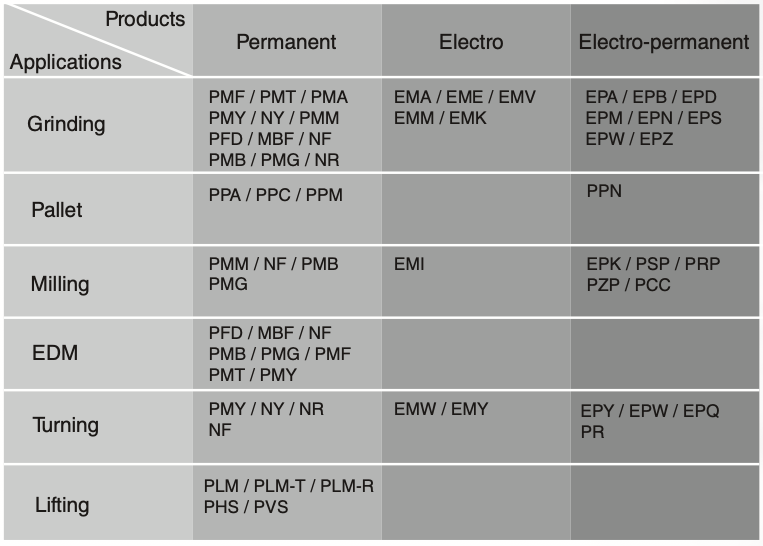

BRISC Magnetics

BRM Brush Research

BRM - Brush Research

BRM Flexhone

B-Safe X System

Carbide Insert Height

Carbide Inserts

Carbide Insert Thickness

Carbide Insert Tolerance

Carbide Saws

CFT Coolant Fed Tooling

CNC Milling

CNC Swiss

CNC Turning

Drilling

George Whalley

GMN USA

Horizon Carbide

IMTS

Inserts

Jergens

Jergens 52-96

Jergens Ball Lock

Jergens Fixture Pro

Machine Tool Monitoring

MAQ

MAQ Devibe Bar

MAQ Digital Protractor

Martindale Saw

Masa Microconic

Micrograd

Pratt Burnerd

Saw Arbor

SOPH Magnetics

SOUTHTEC

Spade Drills

Tapmatic

TapMatic DeBurr-Z

Tapmatic TapWriter

Tech Tips

Toolholder Insert Height

Troubleshooting

Turning: ID Grooving

Turning: OD Grooving

Turning: Threading

WhizCut

WhizCut PZ

WhizHip

WhizTwin

Widen

Workholding

Workholding Magnetic

Archives

June 2024

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

December 2022

November 2022

October 2022

September 2022

August 2022

April 2022

January 2022

July 2021

RSS Feed

RSS Feed